Printing Keychains and Shower Heads: 3-D Printing Goes Beyond the Lab

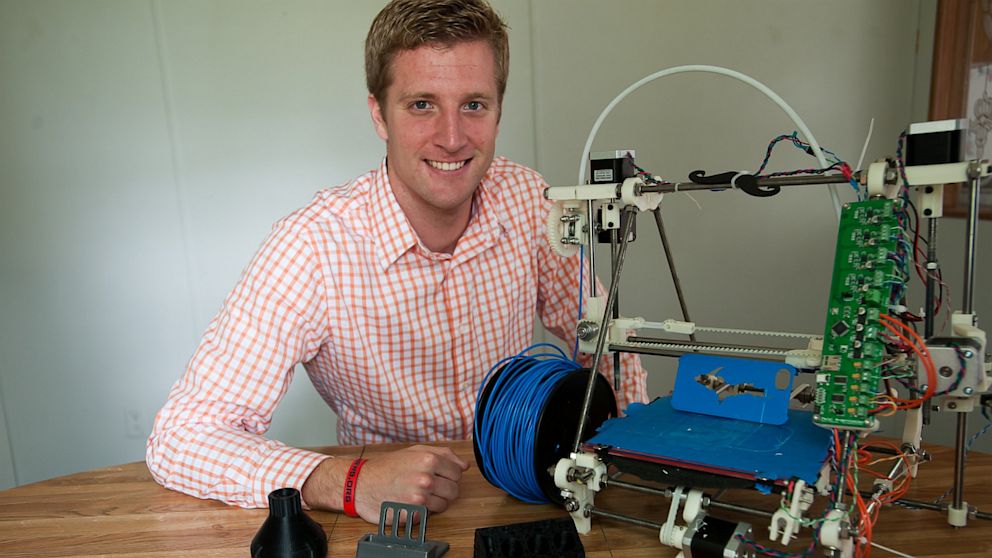

Aug. 6, 2013 — -- At first glance, Ben Wittbrodt's room looks like any other 23-year-old's room, but if you ask him where he got his stuff, you'll get an unexpected answer: a 3-D printer. For those not familiar with the technology, instead of printing ink on paper, these printers squeeze or spray a material, commonly plastic, onto a surface in layers to create a three-dimensional object.

"I've gone through probably around 10 pounds of plastic through my printer," he said. "I've printed out key chains, scale versions of Lego figures four times their actual size, trinkets for my girlfriend."

While 3-D printing has picked up steam with scientists, engineers and even veterinarians, who recently printed a prosthetic leg for a duck, Wittbrodt is one of many who have started to use the technology to print everyday items, including a shower head and trinkets.

Wittbrodt was introduced to the idea of 3-D printing a year ago while doing research as an engineering graduate student at Michigan Technological University. Since then, he's become an expert in the field, writing his master's thesis on it, building his own 3-D printer at home and even running his own 3-D printing business.

3-D Printed Food? NASA to Award Company for 3-D Food Printer

"I've been selling iPhone cases like there's no tomorrow," he said. "I've been printing designs that people can't really find online or go to Apple or Best Buy and find."

3-D printing has been around for a while. The first working 3-D printer was created in 1984, mainly used by companies to create prototypes and architectural models. These industrial grade machines used by professionals in the engineering, architectural and manufacturing industries can cost tens of thousands of dollars. They're also complicated in design, with hundreds of parts in each machine, requiring some 3-D printer knowledge to operate.

For these reasons, they've mostly stayed inside the lab, but associate professor at Michigan Technological University Joshua Pearce recently conducted a study that predicts the three-dimensional printers will be in every home in just a few years.

The study, published in a July issue of Mechatronics Journal, explains 3-D printing is about to go mainstream, and Pearce says the reason is financial.

"We're looking at the next stage where 3-D printing costs have gone down so far that the average family can use it," Pearce said.

A 3-D Printed Cast Lets Broken Arms Breathe

In the study, Pearce and his team worked with 20 common household items listed on Thingiverse, a website containing designs of all sorts of things that can be 3D printed. Ranging from toy figurines of black dragons to customizable bracelets and rings, the designs are used and contributed by members of the community.

Pearce's team then used Google Shopping to find out the maximum and minimum cost of buying those 20 items online and compared the costs to making the items with a 3D printer. The conclusion? It would cost the average consumer anywhere from $312 to $1,944 to buy those 20 things compared to $18 to make them in several hours.

So that's what Wittbrodt did. He has even printed his own showerhead that he has been using for a couple months now. "It's pretty much whenever I'm going through day to day life and I find something or if I break something, and I think I kind of need this, I look online and nine times out of 10 it's already online."

But for the rest of us who don't know how to build our own 3-D printers, there are plenty of companies out there who have done the work for us.