For BigRep, the future of 3D printing and manufacturing is now

Berlin -- Three-dimensional printing has long been billed as the next revolution in manufacturing. But for one Berlin-based start-up, that revolution is taking shape now.

BigRep, a tech firm launched in 2014, is utilizing German engineering to create sophisticated 3D printers - – the largest format-printers in the world for industrial use - and transforming the future of 3D manufacturing.

The company has already been at the forefront of the industry, partnering with global firms such as BASF and Etihad Airways to develop 3D printing solutions for industrial applications.

But this week, as the International Manufacturing Technology Show (IMTS) gets underway in Chicago, the company reportedly will announce yet another game-changing technology that could further revamp the industry.

BigRep is said to introduce a market-ready, high-speed Metering Extruder Technology in its 3D printers, that the company says will revolutionize manufacturing as we know it today. For the first time, 3D printers will now meet the requirements of industrial manufacturing, according to BigRep.

The new technology means a 3D printer equipped with an extruder - one of the most important components on a 3D printer - will be totally controlled (metered) and print out fast. The technology is a first for the industry and will allow 3D printing to move away from the traditional 3D printing niche of prototyping or reverse engineering. It will allow the starting of producing items like other machines do for the production of industrial use parts.

This isn’t the first time that BigRep has made a splash in the 3D printing and manufacturing world. The company, which develops and manufactures the world's largest 3D printers, has been developing forward-thinking technology since its inception, says Stephan Beyer is the CEO at BigRep GmbH.

“For us, it has always been about moving this technology and this industry forward,” said Beyer, who leads an international team of over 90 employees with offices in Boston, New York, and Singapore. Before joining BigRep, Beyer served as investment manager at several internet and telecommunications firms. “We truly see a sort of limitless future for 3D manufacturing,” he says. “And we’re quite happy to be a part at the forefront of broadening the idea and concept of what 3D printing and manufacturing will be.”

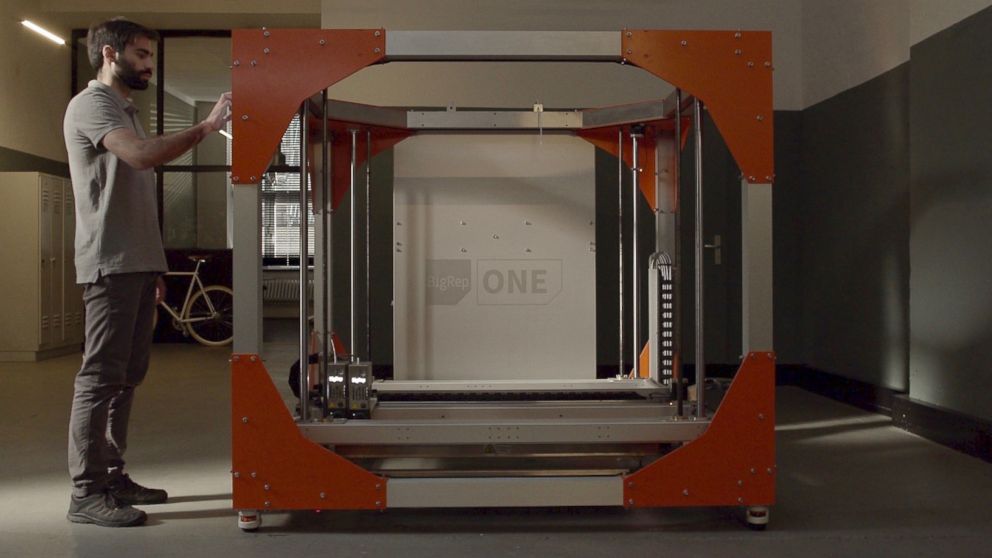

The firm made global headlines when it developed the BigRep ONE, a large-scale 3D printer that can create and manufacture large objects such as mechanical parts or even designer home furnishings. It’s the largest commercially available printer of its type in the world, the company says.

Earlier this year the company printed the world’s first 3D printed airless bicycle tire using its new PRO FLEX material – a TPU-based filament. The filament's flexibility is what makes it work for the bike tires and it can be used for prototyping a variety of objects, including skateboard wheels and automotive gear knobs, BigRep says.

The company also recently created a 3D-printed custom wheel rim for a car, and a group of engineers used a BigRep machine to print out a functional bicycle frame.

The company’s partnerships with BASF and Etihad Airways among others could be a harbinger of things to come in 3D printing and manufacturing.

BigRep’s is collaborating with Etihad Airways Engineering on the development of next-generation additive manufacturing solutions for the aerospace industry.

The plan is to apply 3D printing to the production of novel cabin parts and concepts for both new aircraft and the retrofit installations.

The groundbreaking agreements underscore how the Berlin-based company is quickly becoming one of the leading global providers of large-format 3D printing technology for industrial users, says CEO Beyer.